Taper Reamer: Used to ream holes for tapered pins used on farm machinery and equipment.

(Metal Working-Tools) |

|

Straight Shank Twist Drill:If used on hard steel and at high speeds, it should be made of high speed steel.

(Metal Working-Tools) |

|

Chuck:Used to hold a drill in a drill press or drill motor. May portable drill motors are using keyless chucks that are tightened by hand.

(Metal Working-Tools) |

|

Chuck Key:Used in keyed chuck to tighten or loosen the chuck

(Metal Working-Tools) |

|

Countersink:The shank is 1/4 inch in diameter and can be used in hand or power drills.

(Metal Working-Tools) |

|

Drill Drift:Used for removing morse taper sleeves and tapered shank twist drills from a drill press. Also called a Center Key.

(Metal Working-Tools) |

|

Morse Taper Sleeve:Used as an adaptor to insert different number taper shank twist drills into the drill press.

(Metal Working-Tools) |

|

Reduced Shank Drills:The shank of the drill comes in three sizes, 1/4, 1/2, and 3/4 inch.

(Metal Working-Tools) |

|

Tapered Shank Twist Drill:It should never be used in a chuck.

(Metal Working-Tools) |

|

Diamond Chisel:Use for cutting keyways and groves. Useful for tight places where a cold chisel is too large. Sized by the width of the cutting edge.

(Metal Working-Tools) |

|

Cold Chisel:Size is determined by the width of the cutting edge.

(Metal Working-Tools) |

|

Round Nose Chisel:The sides of the shank are flattened and the width at the cutting edge determines the size.

(Metal Working-Tools) |

|

Cape Chisel:Use for cutting keyways and groves. Useful for tight places where a cold chisel is too large. Sized by the width of the cutting edge.

(Metal Working-Tools) |

|

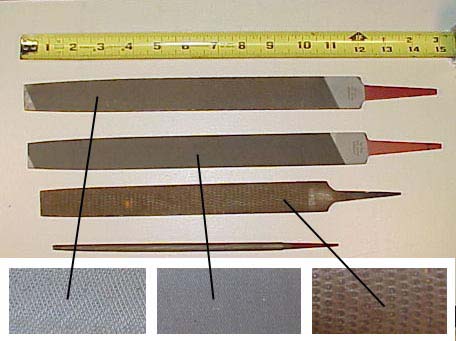

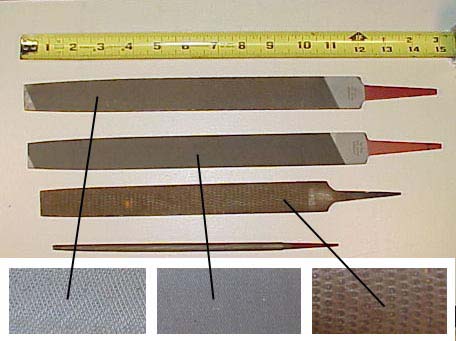

Metal File:Common Shapes: flat, mill, square, half round, round and three square (triangular). Common Coarseness Cuts (rough to smooth): bastard, second cut, smooth. Kinds of Teeth: Single Cut and Double Cut.

(Metal Working-Tools) |

|

Tap Wrench:"T" type tap wrenches have an adjustable chuck.

(Metal Working-Tools) |

|

File Card:The card is a small fine wire brush.

(Metal Working-Tools) |

|

SAE Tap:Used to cut Society of Automotive Engineers or National Fine threads in bored holes and nuts.

(Metal Working-Tools) |

|

USS Tap:Used to cut United States Standard or National Coarse threads in drilled holes or nuts.

(Metal Working-Tools) |

|

Plug Tap:Used to cut threads in machine operations.

(Metal Working-Tools) |

|

Bottoming Tap:Widely used in machine operations to complete a thread in a bottom of a hole.

(Metal Working-Tools) |

|

Taper Tap:Also used to start threads in a blind hole.

(Metal Working-Tools) |

|

Die Stock:Used as a handle for dies.

(Metal Working-Tools) |

|

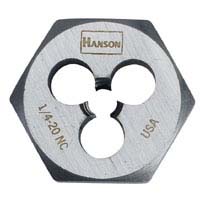

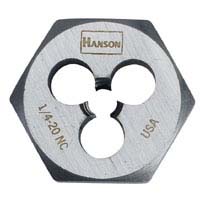

SAE Dies:Used to cut Society of Automotive Engineers of National Fine (NF) Threads on bolts.

(Metal Working-Tools) |

|

USS Die:The die cuts the male thread of a bolt or rod. USS also called National Course (NC) thread.

(Metal Working-Tools) |

|

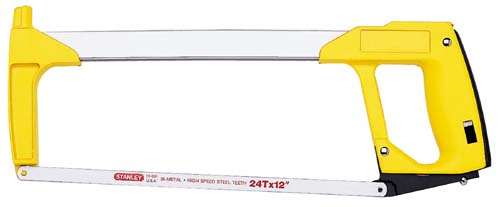

Hack Saw:The handle normally has a pistol type grip.

(Metal Working-Tools) |

|

Screw Extractor:A hole is drilled in the center of the broken stud, and the extractor screwed into the hole in a counter clockwise direction. Also called an easy out.

(Metal Working-Tools) |

|

Whet Stone:Used for sharpening tools such as wood chisels and other tools to a fine edge.

(Metal Working-Tools) |

|

Single Cut File:It has a single series of teeth and is made in bastard cut, second cut and smooth type teeth.

(Metal Working-Tools) |

|

Round File:It is available 4 to 16 inches long and 3/16 to ¾ inches in diameter.

(Metal Working-Tools) |

|

Anvil:Sizes range in weight from 20 to 200 pounds. Used to shape cold and hot metal.

(Metal Working-Tools) |

|

Cut Off Saw:Cutting wheels are disposable. Used for cutting steel bar and pipe.

(Metal Working-Tools) |

|

Shear:A powered hand tool used for cutting sheet metal up to 12 gauge.

(Metal Working-Tools) |

|

Wing Dividers:Divider Tips Are Adjustable By Loosening A Set Screw And Spreading The Tips Apart.

(Metal Working-Tools) |

|

Tin Snip:There are four types available; regular straight snip, curved (left and right) snip, and duckbill snip.

(Metal Working-Tools) |

|

Sheet Metal Layout Rule:It also has circumference measurements on the back side.

(Metal Working-Tools) |

|

Flat Leg Pattern Dividers:Used For Precision Transferring Of Segments From Pattern To Pattern.

(Metal Working-Tools) |

|

Aviation Snips:Available in straight, left, or right. Compound action makes cutting easier and the jaws are usually serrated. Also called Compound snips.

(Metal Working-Tools) |

|

Adjustable Trammel Points:The trammel points can be adjusted to any point on the bar.

(Metal Working-Tools) |

|

Angle Grinder:Available in sizes from 2 to 9 inch. May be used with a grinding, sanding, or wire brush wheel.

(Metal Working-Tools) |

|

Sheet Metal Shear:Foot operated shear

(Metal Working-Tools) |

|

Grinder:Used for sharpening and removing material. Stones are classified by diameter, width, and coarseness (i.e. 1" x 6" 80 grit).

(Metal Working-Tools) |

|

Hydraulic Shear:Powered by a hydraulic pump and cylinder these shears commonly can cut flat stock, angle iron, and punch holes.

(Metal Working-Tools) |

|

Horizontal Band Saw:A band saw designed to cut metal. Typically they have lubrication systems to keep the blade cool.

(Metal Working-Tools) |

|

Fiber Blade:A fiber blade that cuts by abrasion. Typically made with aluminum oxide. Use in the chop saw.

(Metal Working-Tools) |

|

Metal Cutting Blade:A circular blade with carbide teeth designed to cut steel or non-ferrous metals.

(Metal Working-Tools) |

|

Box or Pan Brake:Used for bending sheet metal. Has "fingers" in the clamp that allow bends to be made in box shaped projects.

(Metal Working-Tools) |

|

Cornice Brake:Used for bending sheet metal.

(Metal Working-Tools) |

|

Chop Saw:A power saw designed to cut metal. Can be adjusted to make mitered joints.

(Metal Working-Tools) |

|

Sheet Metal Roller:This machine shapes sheet metal into curved shapes. It has three rollers that adjust to control the radius of the bend.

(Metal Working-Tools) |

|

Bender:The tool is used to bend round and square stock, angle iron, and tubing. It is available with many different dies for various shapes. It many be hand or hydraulic powered.

(Metal Working-Tools) |

|

Dead Blow Hammer:It does not absorb liquids or produce sparks when striking steel objects. Some models are weighted with lead shot.

(Metal Working-Tools) |

|

Engineer's Hammer:Sizes are form 2 1/2 to 4 pound with handle length of 16 inches.

(Metal Working-Tools) |

|

Ball Pein Hammer:This hammer is constructed with a ball at one end and a round crowned hammering face at the other. Also called a Machinist’s Hammer

(Metal Working-Tools) |

|

Hand Drilling Hammer:The head is made in three different sizes, 2, 3, and 4 pound. It has a short handle and can be used in tight places to drive punches and chisels.

(Metal Working-Tools) |

|

Sledge Hammer:Looks like engineers hammer but much larger. 6-12 pounds in weight.

(Metal Working-Tools) |

|

Tinner's Hammer:The hammer head is beveled on one end and has a square face on the other.

(Metal Working-Tools) |

|

Blacksmith's Hammer:The hammering surface is crowned. Designed for use in forming hot metal.

(Metal Working-Tools) |

|

Channel Iron:The common sizes range from 1/2” X 1 inch to 4 X 12 inches.

(Metals) |

|

Stainless Steel:An alloy steel that resists oxidation. Commonly a chrome or nickel alloy of iron.

(Metals) |

|

Copper:It is sold by the piece, running foot or pound.

(Metals) |

|

Cast Iron: Used to make castings for cylinder blocks, plow bottoms, housings for tractor differentials, transmission cases, sprockets wheels, pulleys, pipe fittings and gears.

(Metals) |

|

Brass:It is sold by the piece or by the pound.

(Metals) |

|

Aluminum:It is sold by the square foot, by the piece or by the pound.

(Metals) |

|

Galvanized Steel:The coating varies from 0.0002 inch for the lightest coating to 0.002 inch for water pipe.

(Metals) |

|

Angle Iron:It is sold by the pound. Sized by the length of the legs and thickness. Ex. 2”x2”x1/4”.

(Metals) |

|

Cold Rolled Steel:It is commonly used for making bolts and shafting. Shaped cold the metal is bright and shiny.

(Metals) |

|

Hot Rolled:Available in many shapes. Formed hot the finish is rough and dark.

(Metals) |

|

Square Bar:Ranges in size from 1/8 inch and greater.

(Metals) |

|

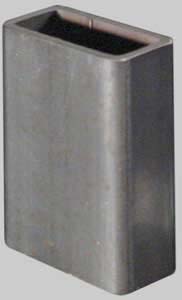

Rectangular Tubing:Unequal dimensions (ex. 2"x4") steel tubing. Wall thickness varies from very light ( ex. .080") to thick in larger sizes (ex. 1/2"). Also see square tubing.

(Metals) |

|

Tool Steel:It can be tempered to various degrees of hardness.

(Metals) |

|

Strip Iron:It is 1/8 inch or less in thickness and comes in various widths.

(Metals) |

|

I Beam:Used to support structures (placed horizontally). Typical lengths 20-40 feet.

(Metals) |

|

Diamond Plate:Sizes range from 1/8 to 1/4 inch thick, 4 to 5 feet in width and 8 to 12 feet in length.

(Metals) |

|

Flat Bar:Size is 3/16 inch thick and greater and comes in a variety of widths.

(Metals) |

|

Expanded Metal:Come in gauge thickness and usually 4 to 5 foot width and 8 to 12 foot lengths.

(Metals) |

|

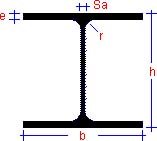

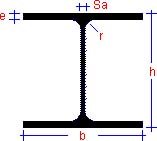

H Beam:A 4 inch H beam is 4 inches wide and 4 inches high.

(Metals) |

|

Square Tubing:Wall thickness varies from very light ( ex. .080") to thick in larger sizes (ex. 1/2"). Heavier wall tubing is excellent for cultivator tool bars because of its smooth exterior finish and ability to with stand heavy loads.

(Metals) |

|